In today’s competitive market, the ability to quickly develop and refine products is a critical factor for success. Traditional manufacturing methods, with their lengthy timelines and high costs, can slow down innovation and limit creativity. Enter commercial 3D printing — a transformative solution that enables businesses to streamline product development processes, from concept to market-ready prototypes.

This article explores how commercial 3d printing services can revolutionize product development, saving time, reducing costs, and driving innovation.

What is Commercial 3D Printing?

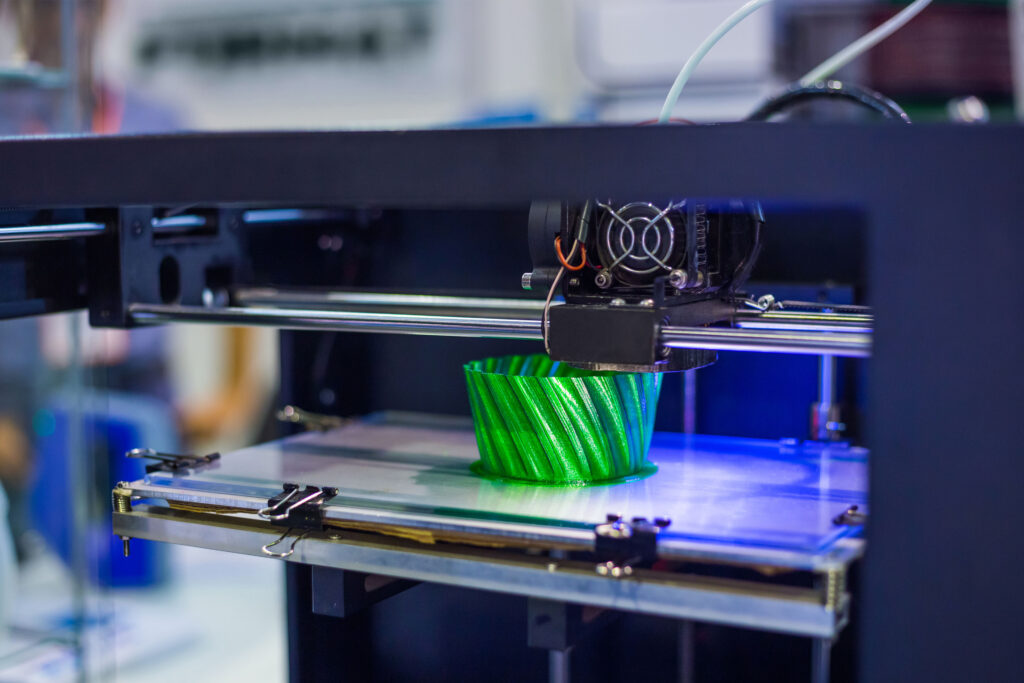

Commercial 3D printing, or additive manufacturing, involves building products layer by layer from a digital design file. Unlike traditional subtractive manufacturing, which cuts away material from a larger block, 3D printing minimizes waste while offering unparalleled design flexibility.

Commercial 3D printing services cater to businesses across various industries, providing fast and efficient solutions for prototyping, design validation, and even small-scale production.

How Commercial 3D Printing Streamlines Product Development

1. Accelerated Prototyping

Creating prototypes using traditional methods often involves complex tooling and lengthy setup times. With 3D printing, businesses can:

- Produce prototypes within days rather than weeks.

- Quickly test and refine designs for functionality and aesthetics.

- Shorten the product development cycle and get to market faster.

2. Cost-Efficient Development

Traditional prototyping methods often require expensive molds and tools, which can be cost-prohibitive for small projects or startups. Commercial 3D printing eliminates these costs, enabling businesses to:

- Create prototypes without investing in specialized equipment.

- Produce only what is needed, reducing waste and material costs.

- Avoid costly errors by iterating on designs affordably.

3. Design Freedom and Innovation

3D printing frees designers from the constraints of traditional manufacturing. Businesses can:

- Experiment with complex geometries and intricate details.

- Incorporate lightweight structures or integrated components.

- Push the boundaries of creativity to develop innovative solutions.

4. Realistic Product Testing

3D printing allows businesses to create prototypes that closely mimic the final product. With high-resolution printers and advanced materials, companies can:

- Evaluate functionality, durability, and performance.

- Identify and resolve design flaws before moving to production.

- Improve overall product quality while reducing development risks.

5. Iterative Development

The iterative nature of 3D printing enables businesses to refine their designs rapidly. This agility allows for:

- Quick modifications based on testing and feedback.

- Multiple design iterations within a single development cycle.

- Better alignment with customer needs and market trends.

Applications of 3D Printing in Product Development

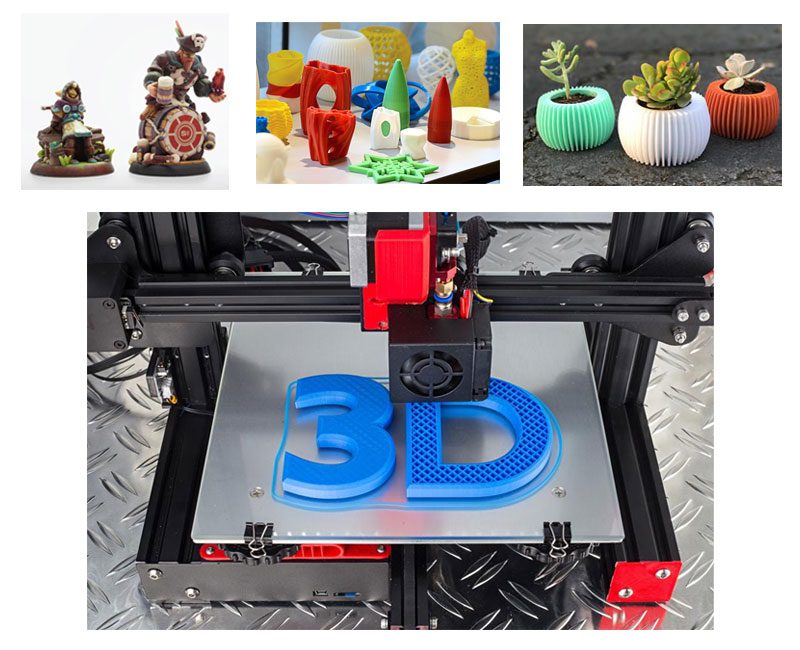

1. Concept Models

3D printing brings ideas to life with tangible models, helping stakeholders visualize concepts and make informed decisions early in the development process.

2. Functional Prototypes

Prototypes can be produced with functional materials, allowing businesses to test real-world applications before committing to full-scale production.

3. Custom Parts and Components

For products requiring unique features or personalization, 3D printing enables the creation of custom parts without additional costs or delays.

4. Pre-Production Validation

Before launching a product, businesses can use 3D printing to validate designs, ensure manufacturability, and gather customer feedback.

Industries Benefiting from 3D Printing in Product Development

- Automotive: Creating lightweight prototypes and testing performance-enhancing designs.

- Healthcare: Developing patient-specific medical devices, implants, and tools.

- Consumer Goods: Producing custom or personalized products to meet customer demands.

- Aerospace: Designing lightweight, high-strength components for aircraft and spacecraft.

- Electronics: Prototyping innovative designs for wearable technology and gadgets.

Benefits of Partnering with Commercial 3D Printing Services

Expertise and Technology Access

Working with a commercial 3D printing service provider gives businesses access to:

- Advanced equipment capable of high-resolution printing.

- A wide range of materials, including metals, plastics, and composites.

- Skilled professionals who can optimize designs for additive manufacturing.

Scalability and Flexibility

Commercial 3D printing services can scale production to meet your needs, whether you require a single prototype or a batch of products.

Time and Cost Savings

Outsourcing 3D printing eliminates the need for in-house equipment and training, reducing overhead costs and freeing up resources for other priorities.

Why 3D Printing is the Future of Product Development

As businesses face growing pressure to innovate quickly and sustainably, 3D printing provides a solution that aligns with these demands. With advancements in materials, speed, and scalability, the technology is becoming increasingly accessible to businesses of all sizes.

Future trends in 3D printing include:

- Integration with AI: Using artificial intelligence to optimize designs for performance and efficiency.

- Material Innovation: Expanding material options for greater durability, flexibility, and eco-friendliness.

- Distributed Manufacturing: Enabling localized production for faster delivery and reduced supply chain disruptions.

Conclusion

Commercial 3D printing is transforming the way businesses approach product development, offering speed, cost savings, and unparalleled design flexibility. By leveraging this technology, companies can streamline their processes, bring innovative products to market faster, and stay ahead in a competitive landscape.

Whether you’re a startup testing a new idea or an established business refining your product line, commercial 3D printing services can be the key to unlocking your full potential. Embrace the future of manufacturing and take your product development to the next level.